Strategic Contamination Control in Nested PCR: A Complete Guide for Reliable Molecular Diagnostics

This article provides a comprehensive framework for researchers and drug development professionals to understand, prevent, and troubleshoot contamination in nested Polymerase Chain Reaction (nested PCR) protocols.

Strategic Contamination Control in Nested PCR: A Complete Guide for Reliable Molecular Diagnostics

Abstract

This article provides a comprehensive framework for researchers and drug development professionals to understand, prevent, and troubleshoot contamination in nested Polymerase Chain Reaction (nested PCR) protocols. Nested PCR's exquisite sensitivity, which allows for detection of low-copy pathogens like Acanthamoeba or Fusarium tricinctum, is paradoxically its greatest vulnerability, making it highly susceptible to amplicon carryover contamination and false-positive results. We explore the foundational sources of contamination, detail rigorous methodological controls including physical laboratory separation and enzymatic decontamination, and offer advanced troubleshooting protocols. Furthermore, we present a comparative analysis of nested PCR against alternative molecular techniques like qPCR, validating its specific niche in sensitive diagnostics when performed with stringent contamination controls, ultimately ensuring data integrity in biomedical research and clinical applications.

Understanding the Enemy: Sources and Consequences of Nested PCR Contamination

Nested PCR is a powerful molecular technique renowned for its high sensitivity and specificity. By using two sets of primers and successive rounds of amplification, it significantly enhances the detection of low-abundance targets, making it invaluable in pathogen detection, genetic studies, and cancer research [1] [2]. However, this exceptional sensitivity comes with a significant trade-off: an increased vulnerability to contamination. This guide explores the reasons behind this susceptibility and provides actionable strategies for researchers to mitigate these risks in their experiments.

FAQ: Understanding Contamination in Nested PCR

What makes nested PCR more prone to contamination than standard PCR?

Nested PCR is particularly prone to contamination due to its two-step amplification process. The primary reason is the need to transfer the first-round PCR product to a second tube for the next amplification round [1] [2]. Each time the reaction tube is opened, there is a risk of introducing airborne contaminants or carryover amplicons from previous reactions into the laboratory environment. Furthermore, because the second round of PCR uses the highly amplified product of the first round as its template, even a minuscule, invisible aerosol droplet containing this product can serve as a potent template, leading to false-positive results [1].

Contamination in PCR laboratories typically originates from four main sources [3]:

- Carryover Contamination: Amplified PCR products from previous reactions are the most common source.

- Cloned DNA: Previously handled plasmid or cloned DNA in the lab.

- Sample-to-Sample Contamination: Can occur during extensive sample processing.

- Exogenous DNA: Environmental DNA present on laboratory equipment, in reagents, or introduced during nucleic acid extraction.

How can I tell if my nested PCR reaction is contaminated?

Signs of contamination include [3]:

- False-positive results: Amplification bands appearing in your negative control reactions (e.g., no-template controls).

- Unexpected bands: Presence of amplification products that do not match the expected size or pattern when analyzed by gel electrophoresis.

A critical step in troubleshooting is always to include and check the results of your negative controls. If the negative control shows amplification, the experiment is compromised by contamination [3].

Troubleshooting Guide: Preventing and Managing Contamination

Preventive Best Practices

The most effective strategy for managing contamination is prevention through rigorous laboratory practice.

- Physical Separation of Workspaces: Establish and strictly maintain separate, dedicated areas for [3]:

- Pre-PCR Area: For reaction setup only. This area should contain dedicated pipettes, tips, reagents, and lab coats. No amplified DNA or post-PCR materials should ever enter this space.

- Post-PCR Area: For PCR amplification, gel electrophoresis, and product analysis. Equipment, including pipettes and the thermal cycler, should remain in this area.

- Use of Aerosol-Barrier Tips: Always use pipette tips with filters to prevent aerosol contamination from pipettes [3].

- Aliquot Reagents: Prepare and store reagents in small, single-use aliquots to minimize repeated exposure and cross-contamination [3].

- Implement UV Irradiation: Use UV light in laminar flow hoods and on work surfaces to degrade any contaminating DNA before and after setting up reactions [3].

- Consider Single-Tube Nested PCR: Where possible, adopt single-tube nested PCR protocols where both primer sets are included in the initial reaction mix, eliminating the need for physical transfer and significantly reducing contamination risk [1].

Decontamination Protocols

If contamination is suspected or occurs, take immediate action to decontaminate your workspace and equipment [3]:

- Surface Decontamination: Thoroughly clean workstations, equipment, and pipettes with a 10% bleach solution, followed by wiping with ethanol or RNAse/DNAse-free water [3].

- UV Irradiation: Leave pipettes and other small equipment under a UV light in a cell culture hood overnight [3].

- Replace Reagents: Discard all current aliquots of reagents (buffers, water, master mix) used in the contaminated experiment and prepare fresh ones [4].

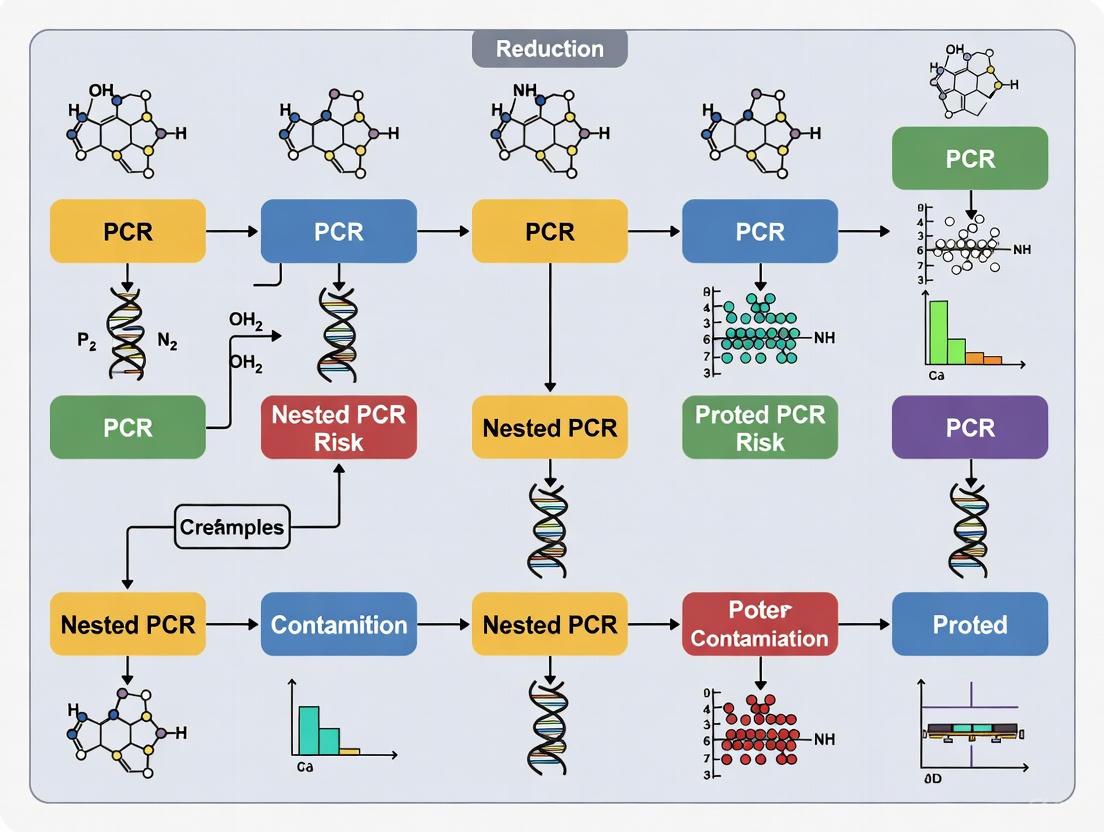

The workflow below illustrates the key contamination risks in the traditional nested PCR process and the primary mitigation strategies.

Quantitative Data on Contamination Risks

The table below summarizes the primary factors that contribute to contamination in nested PCR and their potential impact on experimental results.

Table 1: Factors Contributing to Contamination in Nested PCR

| Factor | Description | Impact on Experiment |

|---|---|---|

| Tube Transfer [1] [2] | Requirement to open tube after first round of amplification to add nested primers or transfer product. | Creates opportunity for aerosol release of highly concentrated amplicons, leading to laboratory-wide contamination and false positives. |

| Extreme Sensitivity [1] [5] | Second round uses product from first round as template, amplifying already amplified material. | Can detect minute levels of contaminating DNA (e.g., from a single aerosol droplet), making false positives likely without stringent controls. |

| Increased Manipulation [1] [2] | Involves more steps and handling than standard PCR. | Prolongs sample exposure to the environment, increasing the probability of introducing contaminants. |

Research Reagent Solutions for Contamination Control

Using the right reagents and materials is fundamental to minimizing contamination risk. The following table lists essential items for a robust nested PCR workflow.

Table 2: Key Reagents and Materials for Contamination Control

| Item | Function | Importance for Contamination Control |

|---|---|---|

| Hot-Start DNA Polymerase [6] | Enzyme activated only at high temperatures, preventing non-specific amplification during reaction setup. | Improves specificity and yield, reducing background that can complicate analysis and be mistaken for contamination [6]. |

| Aerosol-Barrier Pipette Tips [3] | Disposable tips with an internal filter. | Prevents aerosols from contaminating the pipette shaft and subsequent samples, a primary vector for carryover contamination [3]. |

| UV Lamp [3] | Source of ultraviolet light. | Used to irradiate workstations and equipment to degrade contaminating DNA before setting up reactions [3]. |

| Dedicated Pre-PCR Reagents [3] | Buffers, nucleotides, and water aliquoted for PCR setup only. | Stored separately from post-PCR analysis reagents to prevent introduction of amplicons into new reactions [3]. |

| Single-Tube Nested PCR Kits [1] | All reagents and primers for both rounds in one tube. | Eliminates the tube-opening step between amplification rounds, drastically reducing the biggest contamination risk in traditional nested PCR [1]. |

Nested PCR remains a "double-edged sword"—its unparalleled sensitivity is its greatest asset and its most significant vulnerability. The very act of amplifying a target to such a high degree creates a substantial risk of contamination that can compromise experimental integrity. However, by understanding the sources of contamination and rigorously implementing the preventive measures and troubleshooting protocols outlined in this guide—particularly physical workspace separation, meticulous technique, and the adoption of single-tube methods where possible—researchers can confidently wield this powerful technique while safeguarding the validity of their results.

FAQs

The main sources of contamination in nested PCR are:

- PCR Amplicon Carryover: This is the most significant source. A typical PCR can generate up to 10^9 copies of the target sequence. These previously amplified products (amplicons) can aerosolize and contaminate reagents, equipment, and laboratory ventilation systems, leading to false-positive results in subsequent runs [7] [8].

- Cross-Contamination between Samples: This occurs when a sample with a high concentration of the target organism contaminates neighboring samples during handling, nucleic acid extraction, or pipetting [8] [9].

- Environmental Nucleic Acids: Plasmid clones or nucleic acids from previously analyzed organisms can persist in the laboratory environment and be introduced into new reactions [7] [8].

- Contaminated Reagents: Reagents, especially water, can become reservoirs for contaminating DNA if not properly handled and sterilized [9].

Why is nested PCR particularly susceptible to carryover contamination?

Standard nested PCR is highly susceptible because it requires transferring the amplified product from the first PCR reaction to a new tube for the second round of amplification. This process of opening reaction tubes significantly increases the risk of generating aerosols and spilling amplicons, which can then contaminate future experiments [5] [10]. The extreme sensitivity of the technique, designed to detect very low abundance targets, means that even minute amounts of this carryover contamination can be detected and amplified, leading to false positives [11] [8].

What are the most effective strategies to prevent amplicon carryover?

A multi-layered approach is most effective. The core strategies are summarized in the table below.

| Strategy | Description | Key Action |

|---|---|---|

| Physical Segregation | A unidirectional workflow separates pre- and post-PCR activities into different rooms or dedicated spaces to prevent amplicons from entering clean areas [7] [9]. | Move from sample prep → PCR setup → amplification → product analysis without backtracking. |

| UNG/dUTP Treatment | An enzymatic method where dTTP is replaced with dUTP in the PCR master mix. The enzyme Uracil-N-Glycosylase (UNG) is added to new reactions, destroying any contaminating uracil-containing amplicons before amplification begins [7] [8]. | Incorporate UNG enzyme and dUTP in your PCR protocol. |

| Single-Tube Nested PCR | A protocol modification where both amplification rounds occur in the same sealed tube, eliminating the need for transfer and drastically reducing contamination risk [10] [12]. | Adopt single-tube protocols using primers with different melting temperatures or immobilized inner primers. |

| UV Irradiation | Using ultraviolet (UV) light to induce thymidine dimers in contaminating DNA, rendering it unamplifiable [7] [8]. | Expose workstations, instruments, and PCR master mixes (without template) to UV light before use. |

| Chemical Decontamination | Routinely cleaning surfaces and equipment with sodium hypochlorite (bleach), which oxidizes and damages nucleic acids [7] [8]. | Clean work surfaces with 10% bleach followed by 70% ethanol to remove residue. |

How can I decontaminate my laboratory after a contamination event is suspected?

If you suspect a widespread contamination event, take these aggressive steps:

- Discard Reagents: Shut down the laboratory and discard all working solutions, especially water and master mixes [9].

- Thorough Decontamination: Decontaminate all work surfaces, equipment, pipettes, and laboratory coats. Use a 10% bleach solution, followed by ethanol to remove the bleach residue [7] [9].

- Replace Consumables: Autoclave or incinerate contaminated utensils and order new supplies of PCR reagents [9].

- Use Robust Controls: Always include negative controls (No-Template Controls) to monitor for contamination in every run [13] [9].

Experimental Protocols for Contamination Control

Protocol 1: Implementing a Single-Tube Nested PCR

This protocol adapts the traditional two-step nested PCR into a single closed-tube format, dramatically reducing contamination risk by eliminating tube opening between amplification rounds [10] [12].

Workflow Diagram:

Methodology:

- Primer Design and Immobilization: Design two primer sets (outer and inner) targeting the same locus. The inner primers are immobilized on the inside of the PCR tube cap by drying (e.g., with a trace of bromophenol blue) at 37°C [10].

- Reaction Setup: In the bottom of the tube, prepare a standard PCR master mix containing the outer primers, dNTPs, buffer, polymerase, and the DNA template.

- Amplification:

- First Round: Run 15-20 cycles at an annealing temperature high enough to permit binding only for the outer primers. This generates the first amplicon.

- Primer Mixing: Pause the thermocycler at 92°C. Invert the closed tube several times to dissolve the inner primers from the cap into the reaction mixture.

- Second Round: Resume for 30-40 cycles at a lower annealing temperature suitable for the inner primers, which will now amplify the specific product from the first round.

- Detection: Analyze the final product by gel electrophoresis. This method has been shown to achieve a sensitivity of 10-100 target copies [10].

Protocol 2: Pre-Amplification Sterilization with Uracil-N-Glycosylase (UNG)

This method is a widely used pre-amp sterilization technique that can be integrated into any PCR protocol to degrade contaminating amplicons from previous reactions [7] [8].

Workflow Diagram:

Methodology:

- dUTP Incorporation: In all PCR assays, substitute dTTP in the master mix with dUTP. This ensures all newly synthesized amplicons contain uracil instead of thymine [7] [8].

- Sterilization of New Reactions: For a new PCR setup, add the UNG enzyme to the complete master mix (containing dUTP) before adding the new DNA template. Incubate the reaction at room temperature for 10 minutes. During this step, UNG will recognize and hydrolyze the glycosidic bond of uracil in any contaminating, uracil-containing amplicons, breaking the DNA backbone and rendering them unamplifiable [7].

- Enzyme Inactivation and Amplification: Incubate the reaction tube at 95°C for 5 minutes. This heat step inactivates the UNG enzyme so it does not degrade the new uracil-containing products in the upcoming PCR. Proceed with the standard thermal cycling program [8].

Research Reagent Solutions

The following reagents are essential for implementing effective contamination control protocols.

| Reagent/Kit | Function in Contamination Control |

|---|---|

| Uracil-N-Glycosylase (UNG) | Key enzyme in the most widely used method to prevent carryover; cleaves uracil-containing DNA from previous amplifications [7] [8]. |

| dUTP | Used as a substitute for dTTP in PCR master mixes to generate amplicons that are susceptible to cleavage by UNG [7] [8]. |

| Single-Tube Nested PCR Kits | Pre-formulated master mixes optimized for two-round amplifications in a single tube, reducing manipulation and contamination risk. |

| Positive Displacement Pipettes/Tips | Mechanical barriers that prevent aerosol formation during pipetting, reducing sample-to-sample and amplicon cross-contamination [9]. |

| PCR Workstations with UV Light | Dedicated hoods or cabinets equipped with UV lamps to sterilize work surfaces and reaction setups by damaging stray nucleic acids [7] [9]. |

False positives in diagnostic and research PCR protocols represent a critical failure point with consequences that extend far beyond an inconclusive result. In diagnostics, a false positive can lead to unnecessary medical treatments, psychological distress, and substantial healthcare costs. In research, they can invalidate experimental findings, waste precious resources, and derail scientific progress. Within the specific context of nested PCR—a method prized for its high sensitivity in detecting low-abundance targets—the risk of false positives is particularly acute due to the extensive sample manipulation required [1]. This technical support guide provides researchers and drug development professionals with actionable strategies to identify, troubleshoot, and prevent the contamination that leads to false positives.

The first step in mitigating false positives is understanding their origins. Contamination in nested PCR primarily arises from two key sources, each requiring distinct control strategies.

Amplicon Carryover Contamination: This is the single most significant source of false positives [9]. PCR amplicons (the amplified DNA products from previous reactions) are present in extremely high concentrations (up to 10⁹ copies per reaction) and can form aerosols during post-PCR handling steps like tube opening, gel loading, or pipetting [14]. These aerosolized amplicons can contaminate reagents, equipment, and laboratory surfaces, acting as potent templates in subsequent reactions.

Cross-Contamination: This involves the introduction of non-amplified target sequences into the reaction. Sources include cross-contamination between clinical samples during nucleic acid extraction and the use of positive control plasmids or clones [14]. Contamination can be spread by laboratory personnel via hair, skin, clothing, or jewelry and through contaminated equipment like pipettes, vortexers, and lab coats [15] [9].

Physical and Workflow Controls for Contamination Prevention

Implementing rigorous physical barriers and a unidirectional workflow is the cornerstone of an effective contamination control program.

Spatial Separation and Unidirectional Workflow

The most effective strategy is the strict physical separation of laboratory activities into distinct, dedicated areas [15] [14]. Traffic must flow unidirectionally from "clean" to "dirty" areas, with no backtracking.

The following workflow diagram illustrates the recommended unidirectional flow of materials and personnel in a nested PCR laboratory to prevent contamination.

Dedicated Work Areas:

- Pre-PCR Areas (Clean Zones):

- Reagent Preparation Area: A dedicated space for preparing and aliquoting master mixes, primers, and other PCR reagents. This should be the most pristine environment [16] [17].

- Sample Preparation Area: A separate area for nucleic acid extraction and purification from patient samples or research specimens [17].

- Post-PCR Area (Contaminated Zone): A separate room for all activities involving amplified PCR products, including gel electrophoresis, PCR product purification, and sequencing [16] [9]. This area must be located downstream from the clean zones and should contain its own dedicated equipment.

Dedicated Equipment and Consumables

Each designated area must have its own set of equipment and consumables, which must never be moved between areas [9] [14].

- Use dedicated pipettes and pipette tips with aerosol filters for pre-PCR work [16].

- Use color-coded lab coats, gloves, and waste containers for each area to prevent accidental transfer of contaminants [9].

- Aliquot all reagents into single-use volumes to prevent contamination of entire stocks [15] [17].

Biochemical and Technical Strategies

In addition to physical controls, specific biochemical and technical methods can be employed to sterilize potential contaminants and improve reaction specificity.

Key Research Reagent Solutions

The following table details essential reagents and their functions in preventing false positives and enhancing nested PCR reliability.

| Reagent/Material | Function in Contamination Control |

|---|---|

| Uracil-DNA-Glycosylase (UNG) | Enzymatically degrades contaminating uracil-containing amplicons from previous PCRs before amplification begins [15] [14]. |

| dUTP | A nucleotide substitute for dTTP. When used in PCR, it incorporates uracil into new amplicons, making them susceptible to UNG degradation in subsequent runs [14]. |

| Hot-Start DNA Polymerase | Polymerase is inactive at room temperature, preventing non-specific amplification and primer-dimer formation during reaction setup, which reduces background and improves specificity [15] [18]. |

| Aerosol-Barrier Pipette Tips | Prevent aerosols and liquids from entering the pipette shaft, reducing cross-contamination between samples and from pipettes to reagents [9] [17]. |

| 10% Sodium Hypochlorite (Bleach) | Causes oxidative damage to nucleic acids, rendering contaminating DNA unamplifiable. Used for routine decontamination of work surfaces and equipment [15] [14]. |

PCR Technique Modifications for Enhanced Specificity

- Hot-Start PCR: This technique uses a modified DNA polymerase that is inactive until a high-temperature activation step. This prevents non-specific priming and primer-dimer formation that can occur during reaction setup at room temperature, thereby increasing specificity and yield [18].

- Touchdown PCR: This cycling method starts with an annealing temperature higher than the primer's melting temperature (Tm), then gradually reduces it in subsequent cycles. The initial high stringency selectively favors the intended specific primer binding over non-specific binding, reducing false amplification [15] [18].

Detection and Troubleshooting of Contamination

Despite all precautions, contamination can occur. A robust monitoring system is essential for its detection.

Essential Controls for Every Experiment

- No-Template Control (NTC): This is the most critical control for detecting contamination. It contains all PCR reagents except the template DNA, which is replaced with nuclease-free water. A positive signal in the NTC confirms the presence of contaminating DNA in your reagents or master mix [15] [16] [17].

- Positive Control: Contains a known, low-concentration target sequence to verify that the assay is working correctly.

- Negative Control (or Blank): Typically consists of water taken through the nucleic acid extraction process to monitor for contamination during sample preparation.

Troubleshooting Guide: Contamination Incidents

When contamination is detected via your controls, follow this structured troubleshooting guide to identify the source and implement a corrective action.

| Observation | Potential Source | Corrective Action |

|---|---|---|

| No-Template Control (NTC) is positive | Contaminated reagents (water, master mix, primers) or contaminated pipettes used for reagent dispensing. | Discard all aliquots of reagents implicated. Decontaminate pipettes with UV and bleach. Prepare fresh aliquots from clean stocks in a dedicated clean area [17]. |

| Multiple samples and NTC are positive | Widespread amplicon contamination in the laboratory environment or a contaminated piece of shared equipment (e.g., centrifuge, vortexer). | Perform a thorough decontamination of all work surfaces and equipment with 10% bleach [14]. Implement stricter unidirectional workflow and physical separation. Use UNG treatment for all future assays [15]. |

| Only one sample is positive in a run, but it is unexpected | Cross-contamination from another sample during nucleic acid extraction or pipetting. | Use aerosol-barrier tips for all liquid handling. Add template DNA last to the reaction mix. Ensure careful technique to avoid splashing between wells [9]. |

Frequently Asked Questions (FAQs)

Q1: Our lab has a persistent contamination problem that we can't resolve. What is the most drastic but effective action we can take? In a worst-case scenario where contamination is rampant, it may be necessary to perform a "lab reset." This involves discarding all working solutions and reagents, performing a thorough decontamination of all surfaces and equipment with 10% bleach and/or UV irradiation, and ordering new stocks of all PCR reagents. Restart operations with strict adherence to a unidirectional workflow from the outset [9].

Q2: Are there specific risks associated with nested PCR that are different from standard PCR? Yes. The primary added risk in traditional two-tube nested PCR is the requirement to open the reaction tube after the first round of amplification to transfer an aliquot of the product to the second reaction. This step exposes a high concentration of first-round amplicons to the environment, dramatically increasing the risk of carryover contamination. To mitigate this, consider adopting single-tube nested PCR protocols where both primer sets are present but designed to work at different cycling conditions, eliminating the need to open the tube [1].

Q3: How effective is UV light in decontaminating surfaces and reagents? UV light (254 nm) is effective at creating thymidine dimers in DNA, which blocks polymerase extension. However, its efficacy is reduced for short amplicons (<300 bp) and GC-rich sequences. It also cannot penetrate liquids or plastic. Therefore, UV decontamination should be used as an adjunct to bleach cleaning, not as a replacement for it [9] [14].

Q4: What is the role of UNG, and are there any limitations? UNG enzymatically cleaves uracil-containing DNA from previous amplifications. It is highly effective but works best for AT-rich sequences and has reduced activity for GC-rich targets. Furthermore, UNG must be completely inactivated during the initial denaturation step; otherwise, residual activity can degrade your new PCR products. Always store PCR products containing dUTP at -20°C or analyze them immediately after amplification [14].

In molecular diagnostics and research, nested Polymerase Chain Reaction (nested PCR) is a powerful technique used to amplify specific DNA sequences with high specificity. This method involves two successive rounds of PCR amplification using two sets of primers. The second, or "nested," set of primers binds within the product of the first amplification, thereby significantly reducing non-specific binding and amplifying the intended target more reliably [19] [20].

However, the exquisite sensitivity of nested PCR, which is its greatest strength, also makes it particularly vulnerable to contamination. The high number of amplification cycles and the need to transfer first-round PCR products to a second reaction tube dramatically increase the risk of false positives due to amplicon carryover contamination [14] [20]. Contaminating amplification products from previous reactions can build up in the laboratory environment, potentially contaminating reagents, equipment, and ventilation systems. In a clinical setting, the consequences can be very serious, including false test results that lead to inappropriate treatment choices or undue patient stress [21]. Therefore, implementing a robust, multi-layered barrier system is non-negotiable for ensuring the integrity of results in nested PCR protocols.

Mechanical Barriers

Principle and Objective

Mechanical barriers are physical and procedural controls designed to prevent the physical transfer of amplification products from "dirty" post-amplification areas to "clean" pre-amplification areas. The primary objective is to create a unidirectional workflow that eliminates cross-contamination [14].

Implementation Protocols

A strict spatial separation of the laboratory is fundamental. The following workflow must be enforced without exception:

- Reagent Preparation Area: A dedicated, clean room for preparing and aliquoting all master mixes. This area should contain dedicated equipment, laboratory coats, gloves, and aerosol-resistant pipettes. All reagents and disposables must be delivered directly to this area and should never leave and re-enter [14].

- Sample Preparation Area: A separate space for processing clinical or environmental specimens to extract nucleic acids.

- Amplification Area: A designated area for the thermal cyclers where the first and second rounds of PCR are performed.

- Product Analysis Area: A physically separated, contained area where the final amplified products are analyzed, for example, by gel electrophoresis. All traffic must be unidirectional from clean to contaminated areas. Technologists must be alert to the possibility of transferring amplification products on their hair, glasses, jewelry, and clothing from contaminated rooms to clean rooms [14].

Chemical Barriers

Principle and Objective

Chemical barriers involve using chemical agents to degrade or modify contaminating nucleic acids before they can be amplified. These methods target the integrity of the DNA molecule itself, rendering it unsuitable as a template for the DNA polymerase [14].

Implementation Protocols

The most common and effective chemical decontamination agent is sodium hypochlorite (bleach).

- Work Surface Decontamination: Workstations in all areas, but especially in pre-amplification zones, must be routinely cleaned with a 10% sodium hypochlorite solution, followed by ethanol to remove the bleach residue. Bleach causes oxidative damage to nucleic acids, preventing re-amplification [14].

- Equipment and Item Decontamination: Any item that must be transferred from a contaminated area to a clean area (which should be avoided when possible) must be decontaminated. This involves soaking the item in a 2% to 10% bleach solution overnight, followed by extensive washing before transfer [14].

Enzymatic Barriers

Principle and Objective

Enzymatic barriers employ enzymes to selectively destroy contaminating amplicons from previous PCRs before a new round of amplification begins. This is a pre-emptive sterilization step incorporated directly into the PCR mix [14].

Implementation Protocol: The dUTP/UNG System

The most widely used enzymatic contamination control system is the uracil-N-glycosylase (UNG) method.

- Principle: In this system, dTTP in the PCR master mix is partially or fully replaced with dUTP. During amplification, the enzyme incorporates dUTP instead of dTTP, generating amplification products that contain uracil. In subsequent PCR setups, the reaction mix is treated with the UNG enzyme. UNG recognizes and catalyzes the removal of uracil bases from the DNA backbone, generating apyrimidinic sites. When the PCR is initiated and the temperature is raised for the first denaturation step, the DNA backbone fragments at these sites, destroying the contaminating amplicons and rendering them unamplifiable. The subsequent high-temperature step (e.g., 95°C) inactivates the UNG, allowing the new, pristine dUTP-containing amplification products to be synthesized from the natural template [21] [14].

The following diagram illustrates this protective mechanism:

Troubleshooting Guides & FAQs

Frequently Asked Questions

Q1: Why is contamination control especially critical in nested PCR compared to standard PCR? Nested PCR involves two sequential amplification rounds and requires physical transfer of the first-round product, significantly increasing the risk of carryover contamination. Furthermore, the second set of primers can amplify any contaminating first-round amplicons with extreme efficiency, leading to pervasive false positives [20].

Q2: We use UNG. Can we completely disregard physical separation of work areas? No. UNG is highly effective against dUTP-containing amplicons but is ineffective against contamination from natural DNA templates (e.g., high-target concentration in clinical samples) or amplicons from labs that do not use the dUTP/UNG system. Mechanical separation remains the first and most critical line of defense [14].

Q3: What is a No Template Control (NTC), and how do I interpret its results? An NTC is a well that contains all PCR reaction components (primers, master mix, water) but no sample nucleic acid template. It is essential for detecting contamination in reagent components or the environment [21].

- NTC is negative: No contamination is evident. The experiment is valid.

- NTC is positive: Indicates primer-dimer formation or contamination of one or more reaction components with the target sequence. The experiment's results are compromised, and the source of contamination must be investigated [21].

Troubleshooting Common Contamination Issues

| Problem | Possible Cause | Interpretation | Corrective & Preventive Actions |

|---|---|---|---|

| False Positive Results | Amplicon carryover from previous nested PCR runs [14] | Contamination of reagents, equipment, or environment with specific amplification products. | 1. Enforce strict unidirectional workflow [14].2. Implement the dUTP/UNG system in all PCR mixes [21] [14].3. Decontaminate surfaces and equipment with 10% bleach [14]. |

| Contaminated assay components (enzymes, buffers) [21] | Manufacturing process introduced bacterial nucleic acids or synthetic templates. | 1. Use reagents from reputable suppliers.2. Invalidate and replace suspect reagent batches. | |

| False Negative Results | Carryover of inhibitory materials during sample preparation [21] | PCR reaction is inhibited, leading to amplification failure. | 1. Include an internal positive control (IPC) in each reaction [21].2. Repeat sample processing with cleaner nucleic acid extraction. |

| Bubble Formation (in microfluidic chips) | Water vapor permeation and "respiration" in PDMS-made chips [22] | Bubbles displace solution, cause volume loss, and can lead to cross-contamination between reaction units. | Apply a high-pressure liquid seal (above 109 kPa) to effectively prevent bubble formation in PDMS-based devices [22]. |

The Scientist's Toolkit: Essential Research Reagent Solutions

The following reagents and controls are essential for implementing an effective contamination control strategy in nested PCR.

| Item | Function in Contamination Control |

|---|---|

| Uracil-N-glycosylase (UNG) | The core enzyme in the enzymatic barrier; hydrolyzes contaminating dUTP-containing amplicons before PCR begins [21] [14]. |

| dUTP | Used to substitute dTTP in the PCR master mix, creating "sterilizable" amplification products that are susceptible to UNG digestion [14]. |

| Sodium Hypochlorite (Bleach) | The primary chemical barrier; oxidizes and destroys nucleic acids on work surfaces and equipment [14]. |

| Hot-Start DNA Polymerase | A modified polymerase inactive at room temperature. Prevents non-specific amplification and primer-dimer formation during reaction setup, reducing potential background and aiding in the specificity of the nested reaction [6] [23]. |

| No Template Control (NTC) | A critical quality control to monitor for the presence of contamination in reagents or from environmental sources [21]. |

| Internal Positive Control (IPC) | A control sequence added to each reaction to distinguish true target-negative results from PCR inhibition, a common cause of false negatives [21]. |

Building a Fortified Workflow: Practical Protocols for Contamination Prevention

Frequently Asked Questions

Q1: Why is a unidirectional workflow non-negotiable for nested PCR? Nested PCR involves two rounds of amplification, dramatically increasing the risk of amplicon (PCR product) carryover contamination. A unidirectional workflow ensures that amplified DNA products from the second round of PCR or post-amplification analysis are never introduced into the pre-amplification areas where reagents and first-round reactions are prepared. This physical separation is the most critical step in preventing false positives [8] [24].

Q2: What is the most common sign of contamination in my experiments? The most common and reliable indicator is amplification in your No Template Control (NTC) wells. These wells contain all PCR reaction components (primers, master mix, etc.) but no DNA template. Any amplification signal in the NTC indicates that contaminating DNA has been introduced into your reaction [25].

Q3: Can't I just use UV light to decontaminate my workspace instead of physical separation? While UV irradiation is a useful supplementary decontamination method for surfaces and some consumables, it is not a substitute for physical separation. UV light can inactivate exposed amplicons by inducing thymidine dimers, but it may not reach all surfaces effectively and is unreliable for decontaminating liquid reagents [8]. A unidirectional workflow is a proactive, systems-based approach that prevents contamination from occurring in the first place.

Q4: Our lab space is limited. What is the absolute minimum setup required? At a minimum, you must establish two dedicated and physically separated areas:

- Pre-PCR Area: For reagent preparation, sample preparation, and first-round PCR setup.

- Post-PCR Area: For the second round of nested PCR, amplification, and all analysis of PCR products [25] [24]. These areas must have dedicated equipment (pipettes, centrifuges, lab coats, etc.). Technologists should move from the pre- to post-PCR areas, but not back again on the same day without extensive decontamination [24].

Troubleshooting Guides

Problem: Amplification in No Template Control (NTC) Wells

| Observation | Potential Cause | Corrective Action |

|---|---|---|

| Consistent Ct values across all NTC wells | Contaminated reagent (e.g., master mix, water, primers) | Prepare fresh aliquots of all reagents. Replace contaminated stocks [25]. |

| Random Ct values in only some NTC wells | Aerosol contamination during plate setup | Improve pipetting technique; use aerosol-filter tips; centrifuge tubes before opening; review workflow to ensure no amplicons are present [25]. |

| Contamination persists after corrective actions | Widespread environmental amplicon contamination | Perform a deep clean of all pre-PCR surfaces with 10% fresh bleach, followed by 70% ethanol [25] [8]. Implement stricter unidirectional workflow protocols and use UNG enzyme chemistry [25]. |

Problem: High Background or Non-Specific Amplification in Samples

| Observation | Potential Cause | Corrective Action |

|---|---|---|

| Non-specific bands or high background after gel electrophoresis | Contamination from previous nested PCR products | Ensure the second round of PCR is set up in the post-PCR area. Verify that the inner primers are specific and that annealing temperatures are optimized for the second round [26]. |

| General smearing or multiple bands | Carryover contamination degrading assay specificity | Decontaminate workspaces and equipment. Use dedicated pre-PCR lab coats and gloves. Ensure all personnel are trained in contamination avoidance [26]. |

Experimental Protocols for Contamination Control

1. Protocol for Surface Decontamination

- Purpose: To inactivate amplified DNA fragments on work surfaces, equipment, and pipettes.

- Reagents: 10-15% (v/v) sodium hypochlorite (bleach) solution, 70% ethanol, deionized water.

- Procedure:

- Prepare a fresh bleach solution weekly due to its instability [25].

- Apply the bleach solution to the surface and allow it to sit for 10-15 minutes to ensure complete inactivation of DNA [25] [8].

- Wipe down the surface with a paper towel moistened with deionized water to remove bleach residue.

- Follow with a wipe of 70% ethanol to aid in drying and remove any residual water [24].

- Safety: Wear gloves and eye protection when handling bleach solutions [25].

2. Protocol for Using Uracil-N-Glycosylase (UNG) to Prevent Carryover

- Purpose: To enzymatically destroy carryover contamination from previous PCR amplifications prior to the thermocycling of the current experiment.

- Principle: UNG recognizes and removes uracil bases from DNA strands. In this method, dTTP in the PCR master mix is replaced with dUTP. All newly synthesized PCR products will then contain uracil. In subsequent reactions, UNG is added to the master mix and will degrade any uracil-containing contaminant amplicons before PCR begins [25] [8].

- Procedure:

- Reaction Setup: Incorporate dUTP into your PCR master mix instead of dTTP [8].

- UNG Treatment: Include UNG enzyme in the master mix for your next experiment. Incubate the reaction plate at room temperature for 10 minutes before thermocycling. During this step, UNG will cleave any contaminating uracil-containing DNA [8].

- Enzyme Inactivation: Initiate the PCR thermal profile. A first denaturation step at 95°C for 5 minutes will inactivate the UNG enzyme, preventing it from degrading the new uracil-containing products that will be synthesized in the current amplification [8].

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function |

|---|---|

| Aerosol-Resistant Filtered Pipette Tips | Prevents aerosolized contaminants from entering the pipette shaft and contaminating subsequent samples [25]. |

| UNG (Uracil-N-Glycosylase) | An enzymatic system used to destroy carryover amplification products from previous PCR experiments, as detailed in the protocol above [25] [8]. |

| dUTP (Deoxyuridine Triphosphate) | Used as a substitute for dTTP in PCR mixes to generate uracil-containing amplicons that are susceptible to degradation by UNG [8]. |

| 10-15% Bleach (Sodium Hypochlorite) | A potent chemical decontaminant for inactivating DNA on non-porous surfaces and equipment [25] [8] [24]. |

| Aliquoted Reagents | Storing reagents (primers, master mix, water) in small, single-use volumes to prevent repeated freeze-thaw cycles and contamination of a large stock [25]. |

| No Template Control (NTC) | A critical quality control containing all reaction components except the template DNA; used to monitor for the presence of contamination in reagents or the environment [25]. |

Workflow Diagrams

This guide addresses frequently asked questions on essential personal practices for minimizing contamination in sensitive molecular biology workflows, such as nested PCR.

Frequently Asked Questions

1. Why is changing gloves so frequently necessary, and what are the specific guidelines?

The exquisite sensitivity of PCR means that even minute amounts of DNA on gloves can lead to false-positive results. Contamination can originate from previously handled samples, amplicons from post-PCR areas, or the laboratory environment [24] [27].

- When to Change Gloves: The general rule is to wear fresh gloves when starting work in a pre-PCR area and to change them frequently [24]. Specific triggers include:

- Suspected contamination: Change gloves immediately if you suspect they have become soiled with solutions containing template DNA or amplicons [24].

- Moving between work areas: Always change gloves (and lab coat) when moving from a post-PCR area to a pre-PCR area [24] [27].

- During lengthy procedures: While direct studies on PCR are limited, evidence from related fields like arthroplasty surgery suggests that microbiological contamination of gloves increases with time [28]. As a best practice, change gloves at least once per hour during extended pre-PCR setup and whenever moving between critical pre-PCR stations (e.g., from master mix preparation to sample addition) [24] [28].

2. What constitutes proper pipetting technique to prevent aerosol contamination?

Proper pipetting is critical for assay performance and preventing cross-contamination between samples. Incorrect technique can create aerosols that contaminate reagents, pipettes, and adjacent samples [24] [27].

- Use Filter Tips: Always use aerosol-resistant filter tips to prevent aerosol contamination from entering the pipette shaft [27] [16].

- Avoid Splashing: Ensure proper pipetting technique to avoid splashing when aspirating and dispensing liquids [24].

- Handle Tubes Carefully: Open and close all sample tubes and reaction plates carefully to prevent samples from splashing out. A best practice is to briefly spin down (centrifuge) tubes and plates before opening to prevent aerosols from forming when the cap is opened [24].

- Work Methodically: Maintain a calm, organized workflow to avoid accidental spills or splashes.

3. What are the most effective solutions and protocols for surface decontamination?

A rigorous aseptic cleaning technique is a cornerstone of contamination control. Surfaces must be decontaminated to inactivate any DNA present [24] [27].

- Primary Reagent: Diluted Bleach: Sodium hypochlorite (bleach) is highly effective at degrading DNA. The recommended concentration is 10-15% bleach (equivalent to 0.5-1% sodium hypochlorite) [24] [27].

- Decontamination Protocol:

- Clean: Wipe down all work surfaces, pipettors, and touchpoints (e.g., fridge handles) with the freshly prepared bleach solution. Soak the surface for 10-15 minutes to ensure complete inactivation of nucleic acids [24] [27].

- Rinse: After the contact time, use a de-ionized (DI) water-dampened paper towel to wipe away the bleach residue, which can corrode equipment [24] [27].

- Dry (Optional): The surface can be wiped with a 70% ethanol-dampened paper towel to aid in rapid drying [24].

- Frequency: Perform this decontamination before and after each PCR work session and immediately after any spill [24] [27].

4. What do my No Template Control (NTC) results indicate, and how should I respond?

The No Template Control (NTC) is a critical diagnostic for detecting contamination. It contains all PCR reaction components except the DNA template; therefore, any amplification in the NTC indicates contamination [24] [27].

The table below summarizes how to interpret NTC results and recommended actions.

| Observation | Possible Cause | Corrective Actions |

|---|---|---|

| Amplification in all/some NTCs at similar Ct values | Contaminated reagent (e.g., master mix, water, primers) [27] | Replace all reagents with fresh aliquots. Systematically introduce one new reagent at a time to identify the source [27]. |

| Random amplification in NTCs with variable Ct values | Aerosol contamination during reaction setup (e.g., from amplicons in the environment or cross-talk between samples) [27] | Review and improve technique: use aerosol-filter tips, centrifuge tubes before opening, and decontaminate the workspace and equipment thoroughly [24] [27] [16]. |

Decontamination Setup and Workflow

Effective contamination control requires careful preparation and a disciplined, unidirectional workflow.

Preparation is Key:

- Aliquot Reagents: Divide all primers, dNTPs, and buffers into small, single-use aliquots to prevent repeated freeze-thaw cycles and avoid contaminating stock solutions [27] [16].

- Fresh Bleach: Always prepare diluted bleach solutions fresh daily or at least every week, as it degrades and loses effectiveness over time [27].

Logical Workflow: The entire process must flow from "clean" (pre-PCR) to "dirty" (post-PCR) areas, with no backtracking. The following diagram illustrates this unidirectional workflow to prevent amplicon carryover.

Research Reagent Solutions

The table below details key reagents and materials essential for implementing these decontamination practices.

| Item | Function & Rationale |

|---|---|

| Sodium Hypochlorite (Bleach) [24] [27] | The primary chemical for surface decontamination. It effectively degrades DNA contaminants on benchtops and equipment. |

| 70% Ethanol [24] [27] | Used for general cleaning and rapid drying of surfaces after bleach decontamination and rinsing. |

| Aerosol-Resistant Filter Pipette Tips [27] [16] | Create a physical barrier to prevent aerosols and liquids from contaminating the pipette shaft, a common source of cross-contamination. |

| Uracil-DNA Glycosylase (UNG) [8] [27] | An enzymatic method to prevent carryover contamination from previous PCR amplicons. It is included in some master mixes and degrades uracil-containing DNA from prior runs. |

| Laboratory Bleach | Used for general cleaning and rapid drying of surfaces after bleach decontamination and rinsing. |

The dUTP-UNG system is an enzymatic method widely recognized for preventing false-positive results in PCR by eliminating carryover contamination from previous amplification products [8] [29]. This powerful technique is particularly valuable in sensitive applications like nested PCR and when analyzing limited samples, such as in single-cell analysis or liquid biopsies [30].

The system operates on a simple but effective principle:

- dUTP Incorporation: During PCR amplification, deoxyuridine triphosphate (dUTP) is incorporated into newly synthesized DNA amplicons in place of deoxythymidine triphosphate (dTTP) [30] [29]. These uracil-containing amplicons are functionally equivalent to thymine-containing DNA for most downstream applications but possess a critical distinguishing characteristic [29].

- Enzymatic Degradation: In subsequent PCR setups, the reaction mixture is treated with the enzyme uracil-N-glycosylase (UNG) prior to thermal cycling. UNG recognizes and catalyzes the hydrolysis of uracil residues from the sugar-phosphate backbone in any contaminating dUTP-containing DNA [29]. This cleavage creates apyrimidic sites that fragment under the high temperatures of PCR initiation, rendering the contaminants unamplifiable [8] [29].

- Enzyme Inactivation & New Amplification: The UNG enzyme is then thermally inactivated during the initial denaturation step of the new PCR cycle, protecting the newly synthesized dUTP-containing amplicons generated in the current reaction [29].

Experimental Protocols & Workflows

Standard Protocol for Incorporating dUTP-UNG

The following step-by-step methodology is adapted for a target-specific preamplification or standard PCR workflow [30] [8].

Reagent Setup:

- Prepare a master mix using a dNTP blend where dTTP is fully replaced by dUTP [30]. Standard concentration is 0.2 mM for each dNTP, including dUTP [31].

- Include UNG enzyme at a concentration recommended by the manufacturer (e.g., 0.01 - 0.1 U/µL) [8].

- The master mix should also contain all other standard PCR components: primers (0.25 µM), DNA polymerase, PCR buffer, MgCl2 (1.5 mM), and KCl (50 mM) [31].

Step-by-Step Procedure:

Reaction Assembly

- Combine template DNA, master mix, and nuclease-free water to the final desired volume.

- Gently mix and briefly centrifuge the tubes or plates.

UNG Incubation Phase

Enzyme Inactivation & PCR Amplification

- Initiate the thermal cycling protocol with a 5-minute denaturation step at 95°C [8]. This serves two purposes:

- Irreversibly inactivates the UNG enzyme.

- Fragments the sugar-phosphate backbone of UNG-treated contaminant DNA.

- Proceed with the standard cycling parameters for your assay (Denaturation: 90-96°C, Annealing: 40-68°C, Extension: 70-75°C) [31].

- Initiate the thermal cycling protocol with a 5-minute denaturation step at 95°C [8]. This serves two purposes:

Adaptation for Single-Cell Gene Expression Profiling

For sensitive applications like single-cell analysis, a modified protocol demonstrates the system's utility [30]:

Cell Lysis & Reverse Transcription

- Collect individual cells directly into lysis buffer.

- Perform reverse transcription to generate cDNA.

Contamination Control with Cod UNG

- Treat cDNA with Cod UNG (a heat-labile variant) prior to preamplification.

- Key Advantage: Cod UNG can be completely and irreversibly heat-inactivated, preventing any loss of precious preamplification products [30].

Preamplification with dUTP

- Perform target-specific preamplification using a master mix where dTTP is replaced with dUTP.

- This generates sufficient material for multiple downstream qPCR or dPCR analyses while incorporating uracil into all amplicons.

Downstream Quantification

- Use the preamplified product for quantitative analysis via qPCR.

- The protocol successfully eliminates contaminating uracil-containing DNA, even in the presence of a spike-in contaminant, ensuring accurate quantification of rare targets [30].

Performance Data & Comparative Analysis

Quantitative Performance of dUTP vs. dTTP in Preamplification

A comprehensive study using 96 target assays and qPCR compared the performance of dUTP against standard dTTP in preamplification mixes [30].

Table 1: Performance Metrics of dUTP vs. dTTP in Preamplification

| Performance Metric | dTTP (Standard) | dUTP (Experimental) | Statistical Significance |

|---|---|---|---|

| Average Amplification Efficiency | 102% | 94% | p < 0.0001 |

| Reproducibility | Lower | Significantly improved at 3 of 6 concentrations | p < 0.05 |

| Sensitivity (Positive Replicates at Low Concentration) | No significant difference | No significant difference | p > 0.05 |

| Carryover Contamination Elimination after Cod UNG Treatment | Not Applicable | 97% of uracil-containing template degraded | Highly Effective |

Contamination Removal Efficiency

The dUTP-UNG system demonstrates robust degradation of contaminating amplicons, crucial for maintaining assay integrity [30] [32].

Table 2: Contamination Removal Efficiency of the UNG System

| Parameter | Efficiency | Notes |

|---|---|---|

| Overall Template Degradation | 97% average reduction | Across 45 assays [30] |

| Complete Elimination | 34 of 45 assays (76%) | All replicates showed no contamination [30] |

| High Concentration Contamination | Positive correlation with failure | Assays contaminated with high molecule numbers and containing few uracils may still show some contamination post-UNG [30] |

| Sensitivity Limit | >10,000,000-fold reduction | In amplicon concentration shown in RNA virus detection [32] |

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagent Solutions for dUTP-UNG Experiments

| Reagent / Material | Function / Purpose | Example Usage & Notes |

|---|---|---|

| dUTP (Deoxyuridine Triphosphate) | Replaces dTTP as a nucleotide base; incorporated into amplicons, making them susceptible to future UNG degradation [30] [29]. | Use at standard dNTP concentration (e.g., 0.2 mM). Full replacement of dTTP is required for the system to work [30]. |

| UNG (Uracil-N-Glycosylase) | Enzymatic core of the system; hydrolyzes uracil bases in contaminating dUTP-containing DNA from previous runs [8] [29]. | Also known as UDG. Incubate with reaction mix prior to PCR (e.g., 25°C for 10 min or 50°C for 2 min) [8] [29]. |

| Cod UNG (Heat-Labile) | A recombinant UNG from Atlantic cod that can be completely and irreversibly inactivated by heat [30]. | Critical for preamplification protocols and any workflow where residual UNG activity could degrade new dUTP-containing products [30]. |

| dUTP-containing Master Mix | A pre-formulated, optimized mix containing dUTP, UNG, polymerase, buffer, and salts [29] [27]. | Simplifies experimental setup and ensures optimal concentration of all components for robust amplification and contamination control. |

| Positive Control Template | Validates that all PCR components are functional and the amplification is successful [3]. | Should be a well-characterized, confirmed positive sample. Its concentration should not be so high as to pose a contamination risk [33]. |

| No Template Control (NTC) | A critical control containing all reaction components except the DNA template; used to monitor for contamination [16] [27]. | Amplification in the NTC indicates contamination of reagents or the environment with target DNA or amplicons [27]. |

Troubleshooting Guide & FAQs

Frequently Asked Questions

Q1: My PCR efficiency decreased after switching to a dUTP-based master mix. Is this normal and how can I address it?

Yes, a slight decrease in average amplification efficiency is a documented characteristic of dUTP incorporation. Studies show efficiency may drop from 102% (with dTTP) to 94% (with dUTP) [30]. To mitigate this:

- Optimize Primer Design: Ensure primers have dA-nucleotides near their 3' ends so that primer-dimers are efficiently degraded by UNG [29].

- Check Mg²⁺ Concentration: MgCl₂ is a divalent cation required by the DNA polymerase and its concentration (typically 1.5 mM) can affect efficiency [31] [3].

- Verify UNG Compatibility: The sequence being amplified should contain dA and dT (now dU) nucleotides to be a substrate for UNG [29].

Q2: I am performing one-step RT-PCR. Can I use the dUTP-UNG system?

Using standard E. coli UNG in one-step RT-PCR is not recommended. The reverse transcription step occurs at a temperature (typically 50-55°C) that is within the active range of UNG. This would cause the enzyme to degrade the newly synthesized dU-containing cDNA [29].

- Solution 1: Perform reverse transcription and PCR in two separate reactions.

- Solution 2: Use a specialized one-step RT-PCR master mix that employs a heat-labile UNG (e.g., Cod UNG). This variant can be inactivated during the reverse transcription step, protecting the cDNA [29].

Q3: After implementing dUTP-UNG, I still see contamination in my no-template controls. What could be wrong?

The dUTP-UNG system only degrades uracil-containing DNA. If you are still seeing contamination, the source is likely natural thymine-containing DNA [29]. Re-evaluate your laboratory practices:

- Physical Separation: Strictly maintain separate pre- and post-PCR areas with dedicated equipment, lab coats, and consumables [16] [27] [33].

- Decontaminate Surfaces: Regularly clean benches and equipment with 10% fresh sodium hypochlorite (bleach) or 70% ethanol followed by UV irradiation [8] [27] [33].

- Review Workflow: Ensure a unidirectional workflow (pre- to post-PCR) and that no items from the post-PCR area are brought back into the pre-PCR area [16] [33].

Q4: For which specific applications is the dUTP-UNG system NOT suitable?

Avoid using the dUTP-UNG system in the following scenarios:

- Nested PCR where the first-round product is dUTP-containing: UNG will degrade the product needed for the second round of amplification [29].

- Amplification of bisulfite-treated DNA: Bisulfite conversion transforms unmethylated cytosine residues into uracil, making the template a target for UNG degradation [29].

- Genotyping with delayed end-point analysis: If you plan to read the PCR product long after the run is complete, residual UNG activity (in non-heat-labile forms) could degrade your amplicons over time [29].

- Amplification of GC-rich targets with few dT sites: UNG efficacy is tied to uracil content; targets with few thymine (and thus uracil) bases may not be degraded efficiently [30] [27].

Nested Polymerase Chain Reaction (nested PCR) is a powerful molecular technique that significantly enhances the sensitivity and specificity of target DNA amplification by using two sets of primers in sequential reactions. While this method is invaluable for detecting low-abundance targets in clinical, environmental, and research applications, its extreme sensitivity also makes it particularly vulnerable to contamination, especially from previous amplification products (amplicons). This guide provides a comprehensive contamination-aware protocol to help researchers implement robust nested PCR procedures that minimize false positives and maintain experimental integrity.

FAQs: Understanding Nested PCR and Contamination Risks

What is nested PCR and why is it so susceptible to contamination?

Nested PCR is a two-stage amplification method where the product of the first PCR (using "outer" primers) serves as the template for a second PCR (using "inner" or "nested" primers). This sequential amplification significantly increases sensitivity—by as much as 100 to 1000-fold compared to single PCR [34]. However, this extreme sensitivity comes with increased vulnerability to contamination because the laboratory environment becomes saturated with amplification products from previous reactions. The multi-step nature of nested PCR requires additional tube openings and reagent transfers, creating more opportunities for amplicon contamination [8] [34].

There are four main contamination sources in nested PCR:

- Carryover contamination: Amplification products from previous PCRs are the most significant source [3] [8].

- Cross-contamination between samples: Occurs during sample handling and processing [8].

- Cloned DNA or control plasmids: Previously handled in the laboratory [3].

- Environmental DNA: Exogenous DNA present on laboratory equipment, in reagents, or introduced via personnel [3].

How can I distinguish true positives from contamination in my results?

Implementing appropriate controls is essential for identifying contamination:

- No-template controls (NTC): Contain all PCR components except template DNA; if positive, indicate contamination [3] [33].

- Positive controls: Should be carefully selected and used sparingly [33].

- Chimeric positive controls: Novel approaches using engineered control DNA that can be distinguished from natural templates via restriction enzyme digestion help identify carryover contamination [35].

Troubleshooting Guides

Common Nested PCR Problems and Solutions

| Problem | Possible Causes | Solutions |

|---|---|---|

| No amplification products | Incorrect annealing temperature, poor primer design, missing reaction components, PCR inhibitors, insufficient cycles | Recaculate primer Tm, test annealing temperature gradient, include positive control, increase cycles (up to 40), purify template to remove inhibitors [3] [36] [37] |

| Non-specific bands/smearing | Low annealing temperature, primer non-specificity, excess template, enzyme activity at room temperature | Increase annealing temperature incrementally (2°C steps), use hot-start polymerase, reduce template amount, use touchdown PCR [3] [18] [36] |

| Contamination (false positives) | Amplicon carryover, contaminated reagents, improper lab workflow | Implement physical separation of pre-and post-PCR areas, use UNG system, aliquot reagents, UV irradiation of equipment [3] [8] [33] |

| Poor yield in second round | Insufficient product from first PCR, suboptimal dilution, inhibitor transfer | Optimize dilution factor of first PCR product (try 1:10 to 1:1000), ensure efficient first amplification, increase cycles slightly [18] [38] |

Quantitative Data for Nested PCR Optimization

| Parameter | Recommended Range | Notes |

|---|---|---|

| First PCR cycles | 25-30 cycles | Avoid overcycling to reduce amplicon accumulation [3] |

| Second PCR cycles | 20-25 cycles | Fewer cycles than first round to reduce non-specific products [38] |

| Template dilution | 1:10 to 1:1000 | 10-fold dilutions typically used between first and second rounds [3] [38] |

| Annealing time | 5-15 seconds | Shorter times enhance specificity, especially for PrimeSTAR polymerases [3] |

| Primer concentration | 0.1-1 μM | Optimize for each primer set; high concentrations promote primer-dimers [36] [37] |

Step-by-Step Contamination-Aware Protocol

Pre-PCR Preparation: Laboratory Setup and Reagent Preparation

Physical Laboratory Separation

- Establish three distinct work areas: (1) reagent preparation, (2) sample preparation/template addition, and (3) amplification product analysis [8] [33].

- Maintain unidirectional workflow—never bring equipment or reagents from post-PCR areas back to pre-PCR areas [3] [33].

- Each area should have dedicated equipment (pipettes, tips, centrifuges, lab coats) [33].

Reagent Preparation

- Aliquot all reagents to avoid multiple freeze-thaw cycles and contamination of master stocks [33].

- Prepare master mixes in a laminar flow cabinet equipped with UV light [3] [33].

- Use aerosol-resistant filter tips for all pipetting steps [33].

- Include appropriate controls: no-template, positive, and negative extraction controls [33].

Nested PCR Procedure with Contamination Controls

First Round PCR

- Prepare master mix on ice in the reagent preparation area: Note: For additional protection, substitute dTTP with dUTP in the master mix to enable subsequent UNG treatment [8].

Add template DNA in the sample preparation area.

Thermal cycling conditions:

- Initial denaturation: 94-95°C for 2-5 minutes

- 25-30 cycles of:

- Denaturation: 94-95°C for 30 seconds

- Annealing: Temperature specific to outer primers for 5-15 seconds [3]

- Extension: 72°C for 1 minute/kb

- Final extension: 72°C for 5-10 minutes

Inter-Round Transfer

- Dilute first-round PCR product (typically 1:10 to 1:100) in the sample preparation area [3] [38].

- Centrifuge tubes before opening to avoid aerosol formation [33].

Second Round PCR

- Prepare master mix in the reagent preparation area using inner primers.

- Add diluted first-round product as template in the sample preparation area.

- Use the same thermal cycling conditions as the first round, but with 20-25 cycles.

Post-Amplification Analysis

- Analyze PCR products in the dedicated post-amplification area.

- Never bring amplification products back to pre-PCR areas.

- Clean work surfaces with 10% sodium hypochlorite (freshly prepared) or commercial DNA-decontaminating solutions after use [8] [33].

- Decontaminate equipment with UV irradiation (254 nm for 5-20 minutes) [8].

Advanced Contamination Control Strategies

Enzymatic Control: Uracil-DNA Glycosylase (UNG) System

The UNG method is one of the most effective techniques for preventing carryover contamination:

- Incorporation: Substitute dTTP with dUTP in all PCR mixes, resulting in uracil-containing amplicons [8].

- Contamination Elimination: Before PCR, treat reactions with UNG at room temperature for 10 minutes to degrade any uracil-containing contaminants from previous reactions [8].

- Enzyme Inactivation: UNG is thermally inactivated at 95°C for 5 minutes prior to the actual PCR cycles [8].

Workflow Visualization

Alternative Approaches to Reduce Contamination Risk

Single-Tube Nested Real-Time PCR

Chimeric Positive Controls

- Engineered control plasmids that generate amplicons distinguishable from natural targets via restriction enzyme digestion [35].

- Allows rapid identification of carryover contamination versus true positive results.

The Scientist's Toolkit: Essential Research Reagent Solutions

| Reagent/Equipment | Function in Contamination Control | Implementation Notes |

|---|---|---|

| Hot-start DNA polymerase | Reduces non-specific amplification and primer-dimer formation by inhibiting enzyme activity until high temperatures are reached [18] | Enables room temperature setup without compromising specificity |

| UNG system | Prevents carryover contamination by degrading uracil-containing amplicons from previous reactions [8] | Requires substitution of dTTP with dUTP in all PCR mixes |

| Aerosol-resistant filter tips | Prevents aerosol contamination of pipettors and cross-contamination between samples [33] | Essential for all pipetting steps; confirm compatibility with your pipettes |

| DNA decontamination solutions | Destroys contaminating DNA on work surfaces and equipment [33] | 10% sodium hypochlorite (freshly made) or commercial DNA-destroying products |

| Dedicated equipment and lab coats | Prevents transfer of amplicons between work areas [3] [33] | Color-coding different areas helps prevent accidental transfer |

| UV irradiation equipment | Damages contaminating DNA through thymidine dimer formation [3] [8] | Effective for decontaminating surfaces, tools, and equipment; 254 nm wavelength |

Implementing a contamination-aware nested PCR protocol requires meticulous attention to laboratory workflow, physical separation of pre-and post-amplification activities, and strategic use of enzymatic controls. By adopting these practices—including the UNG system, proper laboratory zoning, and rigorous use of controls—researchers can leverage the exceptional sensitivity of nested PCR while minimizing the risk of false positives due to contamination. These measures are particularly crucial in diagnostic, clinical, and regulatory settings where result accuracy directly impacts patient care, research validity, and regulatory decisions.

In nested PCR protocols, where the amplification of specific DNA sequences is paramount, the risk of contamination poses a significant threat to experimental integrity. Minute airborne particulates or aerosolized amplicons from previous reactions can lead to false positives, rendering data unreliable. This technical support center outlines the systematic use of laminar flow hoods and ultraviolet (UV) decontamination to establish a controlled, contaminant-free workspace, thereby safeguarding the accuracy of your molecular research and drug development processes.

Laminar Flow Hood Fundamentals and Classification

What is a Laminar Flow Hood?

A laminar flow hood, also known as a clean bench, is a piece of laboratory equipment designed to provide a sterile, particulate-free workspace. It achieves this by drawing air through a High-Efficiency Particulate Air (HEPA) filter and projecting it across the work surface in a smooth, laminar, non-turbulent flow. This constant stream of clean air protects the items placed within the hood from contamination by particulates such as dust, airborne microbes, and aerosol particles [39] [40].

Types of Laminar Flow Hoods

Laminar flow hoods are categorized based on the direction of airflow. The table below summarizes the two main types.

Table: Comparison of Laminar Flow Hood Types

| Feature | Horizontal Laminar Flow (HLF) | Vertical Laminar Flow (VLF) |

|---|---|---|

| Airflow Direction | Air flows horizontally from the back of the hood, across the work surface, and towards the user [41]. | Air flows vertically from the top of the hood, down over the work surface [41]. |

| Product Protection | Excellent; the sample is downstream of the filter and upstream of the user or environment. | Excellent; creates a curtain of clean air between the user and the work surface. |

| User Protection | Does not protect the user; not suitable for hazardous materials [41]. | Offers better operator protection than horizontal flow, but still not designed for hazardous materials [41]. |

| Common Applications | Electronics assembly, media plate preparation, and non-hazardous sample manipulation. | Pharmaceutical preparations, medical device manufacturing, and sensitive microbiological work [41] [39]. |

Cleanroom Classifications and Laminar Flow Hoods

Laminar flow hoods create a micro-environment that typically meets the requirements for an ISO 5 (Class 100) cleanroom, which is significantly cleaner than the ISO 8 (Class 100,000) cleanrooms common in medical device manufacturing areas [39]. The following diagram illustrates the typical workflow for establishing and maintaining this sterile environment.

UV Decontamination: Principles and Safety

How Does UV Sterilization Work?

Ultraviolet (UV) sterilization is a disinfection technique that uses short-wavelength UVC light (in the range of 200 to 280 nanometers) to kill or inactivate microorganisms [42]. The mechanism is biochemical: UVC photons are absorbed by the microorganism's DNA and RNA, causing covalent bonds to form between adjacent thymine (in DNA) and uracil (in RNA) molecules [42]. This creates structural abnormalities (thymine dimers) that disrupt genetic replication and function, rendering the microorganism unable to reproduce and effectively inactivating it [42].

Integrating UV Lamps in Laminar Flow Hoods

Many laminar flow hoods are equipped with an optional UVC lamp as an added layer of protection [41]. This lamp is used to sterilize the interior work surface and the contents within the hood between operational periods, typically before and after work sessions [41] [42]. It is crucial to note that the UV light is intended for surface decontamination when the hood is not in use, as it does not sterilize the air during active airflow.

Critical Safety Protocols for UV Light

UVC light is harmful to both skin and eyes. Strict safety protocols must be followed:

- Never be present when the UV light is on. Some hoods are equipped with safety features, such as motion sensors that automatically switch off the UV light when movement is detected [42].

- If you must handle the UV lamp, wear appropriate Personal Protective Equipment (PPE), including UV-blocking safety glasses and gloves [42].

- Ensure the hood's sash or night door/cover is closed when the UV light is activated to contain radiation [41].

Troubleshooting Guides and FAQs

Frequently Asked Questions

Q: Can I use a laminar flow hood for working with pathogenic agents?

- A: No. Standard laminar flow hoods are designed only for product protection. They direct air toward the user and are not safe for handling hazardous, toxic, or pathogenic materials. For such work, you must use a Biosafety Cabinet (BSC), which is designed to provide both product and personnel protection [41].

Q: Why is my laminar flow hood not maintaining a uniform airflow velocity?

- A: A common cause is a clogged HEPA filter. The filter has a finite lifespan and must be replaced when airflow drops below the required level. Other causes can include a faulty blower motor or an obstruction in the pre-filter or ductwork.

Q: How long should I run the UV light to effectively decontaminate the hood?

- A: A typical sterilization cycle runs for a minimum of 15-30 minutes. However, the required time can vary based on the lamp's intensity and the level of contamination. Consult the manufacturer's instructions for specific guidance.

Q: I see a growth in my negative control during nested PCR. Could hood contamination be the cause?

- A: Yes. While the hood protects your work, the UV lamp does not sterilize the air during use. Aerosolized amplicons from previous nested PCR runs can contaminate the workspace. Ensure you decontaminate all surfaces, pipettes, and equipment with a validated disinfectant (e.g., 10% bleach followed by 70% ethanol) and use dedicated consumables within the UV-sterilized hood.

Q: The UV lamp in my hood has stopped working. What should I check?

- A: First, ensure the lamp has not reached the end of its usable life (typically 8,000-9,000 hours). If it is within its lifespan, check the electrical connections and the lamp starter. Always refer to the manufacturer's troubleshooting guide and de-energize the unit before any inspection.

Troubleshooting Common Issues

Table: Troubleshooting Laminar Flow Hood and UV Lamp Problems

| Problem | Potential Causes | Corrective Actions |

|---|---|---|

| Low or No Airflow | 1. Clogged HEPA filter.2. Faulty blower motor.3. Obstructed pre-filter. | 1. Replace HEPA filter.2. Contact service technician.3. Clean or replace pre-filter. |

| UV Lamp Not Turning On | 1. Lamp has reached end of life.2. Ballast or starter failure.3. Loose electrical connection. | 1. Replace the UV lamp.2. Replace ballast/starter.3. Check and secure connections (with power off). |

| Turbulent Airflow | 1. Large object obstructing airflow.2. Improperly placed equipment.3. Room with strong air currents. | 1. Remove obstruction.2. Rearrange work area to minimize disruption.3. Relocate hood away from vents/doors. |

| PCR Contamination | 1. Inadequate surface decontamination.2. Aerosolized amplicons in the environment.3. UV cycle not run or ineffective. | 1. Clean with 10% bleach and 70% ethanol.2. Use aerosol-resistant tips and dedicated equipment.3. Ensure adequate UV exposure time; verify lamp output. |

The Scientist's Toolkit: Research Reagent Solutions

For researchers conducting sensitive nested PCR protocols, maintaining the integrity of reagents is critical. The following table details essential materials and their functions in contamination control.

Table: Essential Materials for Contamination Control in Nested PCR

| Item | Function | Application Note |

|---|---|---|

| HEPA Filter | Removes 99.97% of airborne particles ≥0.3 µm, creating the sterile work zone [39]. | The core component of a laminar flow hood; requires periodic replacement. |

| UVC Germicidal Lamp | Decontaminates the work surface by damaging microbial DNA/RNA between uses [41] [42]. | Used when the hood is unoccupied; not for real-time air sterilization. |

| Nuclease-Free Water | Free of RNases and DNases, preventing degradation of nucleic acids and reagents. | Essential for preparing PCR master mixes and dilutions. |

| Aerosol-Resistant Barrier Tips | Prevent pipette tip aerosols from contaminating the sample or the pipette shaft. | A first line of defense against cross-contamination between samples. |

| Surface Decontaminants | Inactivates nucleic acids and microbes on work surfaces and equipment. | A 10% sodium hypochlorite (bleach) solution is effective for destroying DNA amplicons. |